Mea hana akamai akamai o na mea conductive thermal

10+ Makahiki Hana Hana

- tiger.lei@jojun.net

- +86 512-50132776

JOJUN-6800 Series Thermal Pad

★ Nā mea maʻamau o JOJUN-6800 Series Thermal Pad

| ʻO nā mea maʻamau o JOJUN6800 | |||

| Waiwai | Unite | Huahana Huahana | ʻAno hoʻāʻo |

| JOJUN6800 | |||

| kalakala |

| Hoʻopilikino ʻia | Nānā |

| mānoanoa | mm | 0.5-5 | ASTM D374 |

| kikoʻīKaumaha | g/cc | 3.4 | ASTM D792 |

| ʻoʻoleʻa | Kahakai oo | 20-70 | ASTM D2240 |

| Palapala noiMahana | ℃ | -50 - +200 |

|

| Ka hikiwawePapa |

| V0 | UL94 |

| MāmāʻO ka hoʻokō | W/mK | 8 | ASTM D5470 |

| HaʻihaʻiVoltage | KV/mm | >6 | ASTM D149 |

| VolumeKū'ē | ohm-cm | 10 ^14 | ASTM D257 |

| DielectricMau | 1MHz | 7 | ASTM D150 |

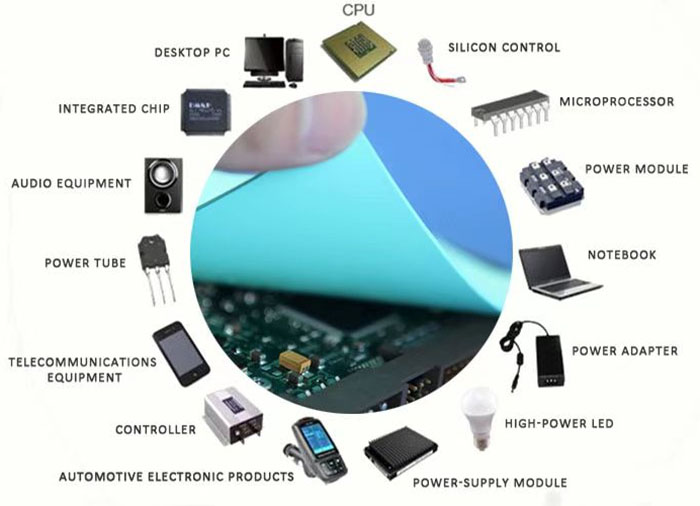

★ Noi

CPU

ʻO nā mea ʻoluʻolu e hoʻopaʻa i ka chassis

Kiʻekiʻe ka māmā holo waihona waihona

Hoʻokele GPS a me nā mea lawe lima ʻē aʻe

LED TV a me nā kukui LED

Module hoʻomanaʻo RDRAM

Hoʻonā wela wela micro

★ Kaʻina Hana Hana

Hoʻohuihui

Extrusion

Laina Hana Papa Thermal

ʻOhi

Pūʻolo

Waiwai Puka

★R&D Center

ʻO ka mea hōʻike hoʻohaʻahaʻa uila

ʻO ka mea hōʻike wela wela

Kneader

Hale Hana

★ Nā hiʻohiʻona a me nā pono

ʻO RoHS kūpono

ʻIke ʻia ʻo UL

ʻO ka hoʻokele wela maikaʻi: 5.0 W/mK

ʻAʻole pono ka uhi paʻa hou

ʻO ka hana wela koʻikoʻi

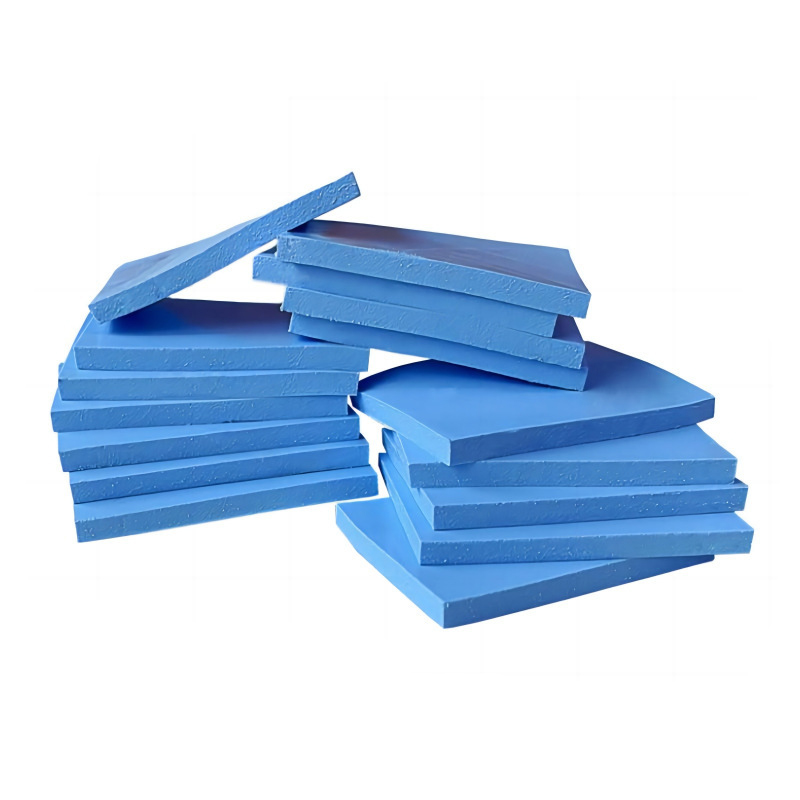

Loaʻa i ka mānoanoa like ʻole

Hoʻokuʻu maʻalahi ka hana

★ Palapala

Nā hiʻohiʻona o nā huahana Thermal

-

Nā hiʻohiʻona o Thermal Pad

1. He maikaʻi ka wela wela: 1-15 W / mK.

2. ʻO ka paʻakikī haʻahaʻa: Aia ka paʻakikī mai Shoer00 10 ~ 80.

3. Hoʻopili uila.

4. Maʻalahi e hui. -

Nā hiʻohiʻona o ka Thermal Paste

1. ʻElua ʻāpana hoʻopihapiha hoʻopihapiha hoʻopihapiha, hoʻopili wai.

2. Thermal conductivity: 1.2 ~ 4.0 W/mK

3. ʻO ka hoʻokuʻu uila kiʻekiʻe, ka paʻa kiʻekiʻe, ke kūpaʻa wela maikaʻi.

4. Ke noi hoʻoemi, hiki ke hoʻokō i nā hana automated. -

Nā hiʻohiʻona o ka Thermal Grease

1. Hoʻokaʻawale aila haʻahaʻa (i ka 0).

2. Keʻano lōʻihi lōʻihi, hilinaʻi maikaʻi.

3. Ke kū'ē kū'ē i ka wā (kiʻekiʻe a me ka haʻahaʻa haʻahaʻa -40 ~ 150 ℃).

4. Ke kū'ē i ka wai, ke kū'ē ozone, ke kū'ē kahiko.