Mea hana akamai akamai o na mea conductive thermal

10+ Makahiki Hana Hana

- tiger.lei@jojun.net

- +86 512-50132776

JOJUN-8900 Series Thermal Paste

★ Nā mea maʻamau o JOJUN-8900 Series Thermal Paste

| ʻO ka hoʻokele welaHoʻopili | |||

| Waiwai | Unite | Huahana Huahana | ʻAno hoʻāʻo |

| JOJUN-8350 | |||

| kalakala |

| Hinahina | Nānā |

| ʻO ka mānoanoa | g/cc | 3.1 | ASTM D792 |

| ʻO ka wikiwiki Extrusion@30cc, 90psi | g/min | 10-90 |

|

| Palapala noiMahana | ℃ | -50~+200 |

|

| Ka hikiwawePapa |

| V0 | UL94 |

| MāmāʻO ka hoʻokō | W/mK | 3.5 | ASTM D5470 |

| HaʻihaʻiVoltage | KV/mm | >5 | ASTM D149 |

| VolumeKū'ē | ohm-cm | 10^13 | ASTM D257 |

| DielectricMau | 1MHz | 7 | ASTM D150 |

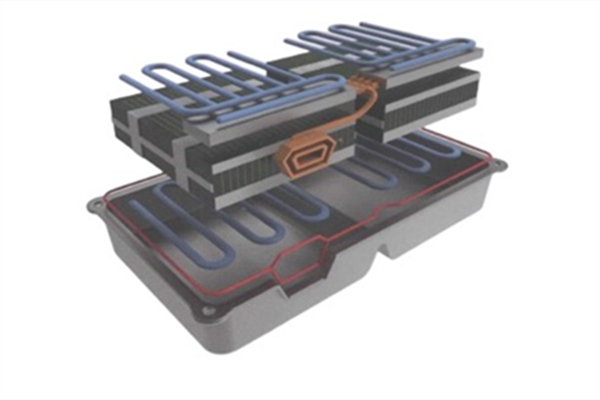

★ Noi

ʻĀpana LED

lako kamaʻilio,

PPU kelepona paʻalima,

Module hoʻomanaʻo,

IGBT

Nā modula mana,

Kahua semiconductor mana.

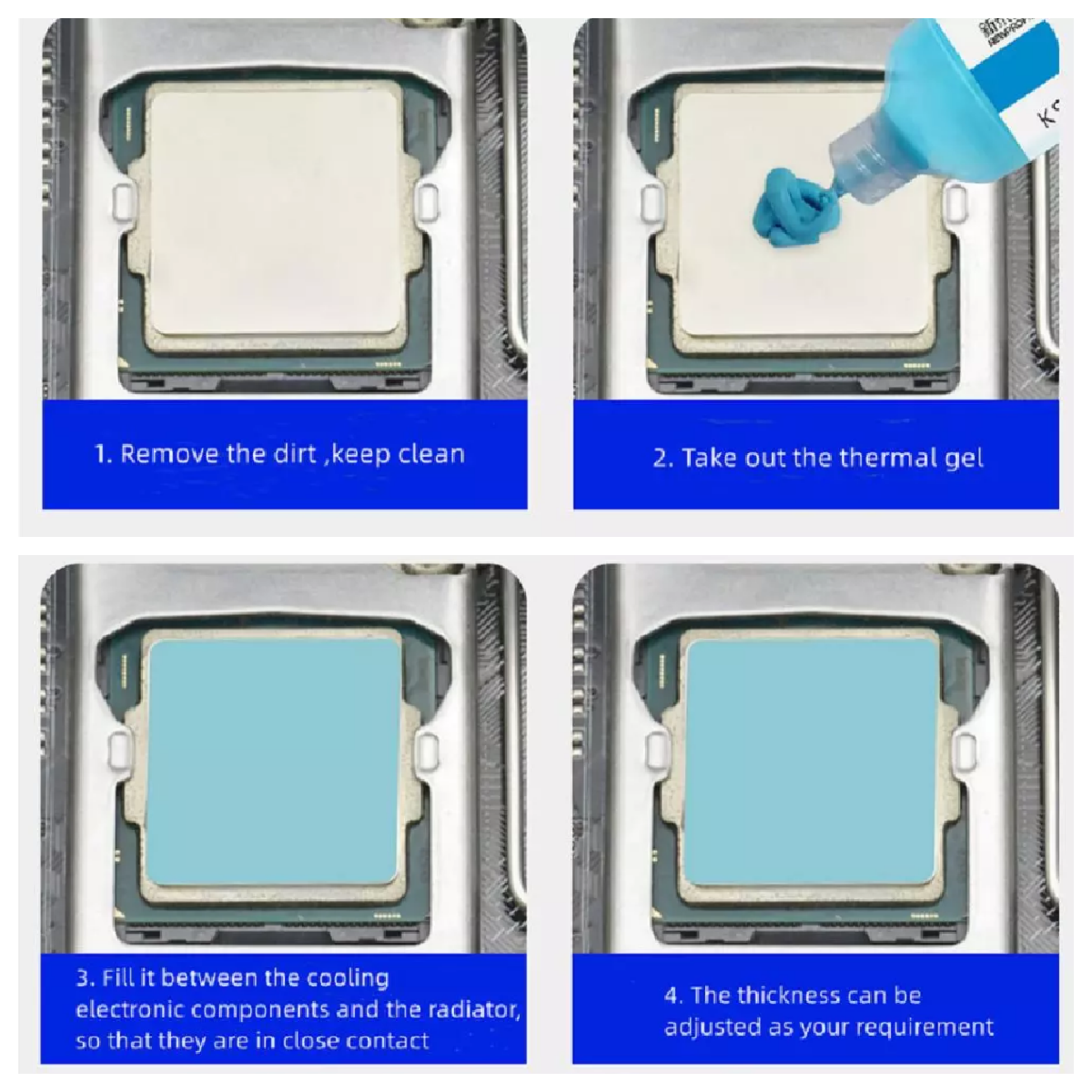

★ Hoʻohana

★ Kaʻina Hana Hana

Hoʻohuihui

Extrusion

Laina Hana Papa Thermal

ʻOhi

Pūʻolo

Waiwai Puka

★R&D Center

ʻO ka mea hōʻike hoʻohaʻahaʻa uila

ʻO ka mea hōʻike wela wela

Kneader

Hale Hana

★ Nā hiʻohiʻona a me nā pono

ʻO ka hoʻoili wela maikaʻi: 9 W/MK

ʻElua mau mea, maʻalahi e mālama;

ʻOi aku ka maikaʻi o ke kiʻekiʻe a me ka haʻahaʻa haʻahaʻa haʻahaʻa mechanical waiwai a me ka paʻa kemika;

Hiki ke hoʻololi i ka manawa curing e like me ka mahana.

Hiki ke hoʻohana 'ia nā mea 'akomi e hoʻololi i ka mānoanoa;

Hoʻohana maʻalahi no ka hana ʻakomi o ka ʻōnaehana dispensing.

★ Palapala

Nā hiʻohiʻona o nā huahana Thermal

-

Nā hiʻohiʻona o Thermal Pad

1. He maikaʻi ka wela wela: 1-15 W / mK.

2. ʻO ka paʻakikī haʻahaʻa: Aia ka paʻakikī mai Shoer00 10 ~ 80.

3. Hoʻopili uila.

4. Maʻalahi e hui. -

Nā hiʻohiʻona o ka Thermal Paste

1. ʻElua ʻāpana hoʻopihapiha hoʻopihapiha hoʻopihapiha, hoʻopili wai.

2. Thermal conductivity: 1.2 ~ 4.0 W/mK

3. ʻO ka hoʻokuʻu uila kiʻekiʻe, ka paʻa kiʻekiʻe, ke kūpaʻa wela maikaʻi.

4. Ke noi hoʻoemi, hiki ke hoʻokō i nā hana automated. -

Nā hiʻohiʻona o ka Thermal Grease

1. Hoʻokaʻawale aila haʻahaʻa (i ka 0).

2. Keʻano lōʻihi lōʻihi, hilinaʻi maikaʻi.

3. Ke kū'ē kū'ē i ka wā (kiʻekiʻe a me ka haʻahaʻa haʻahaʻa -40 ~ 150 ℃).

4. Ke kū'ē i ka wai, ke kū'ē ozone, ke kū'ē kahiko.